Fence Hardware's

Tension Bands

Tension bands are flat, sturdy metal bands specifically designed to attach the chain link fabric to terminal posts, such as end, corner, and gate posts.

They wrap around the post and secure the fabric firmly in place.

• Material: These bands are constructed from galvanized steel, which is treated to resist corrosion and withstand various weather conditions.

This material choice ensures longevity and durability, maintaining the structural integrity of the fence over time.

• Function: Tension bands play a crucial role in securing the chain link fabric to the terminal posts.

By fastening the fabric at critical points, they help ensure that the fence remains taut, properly aligned, and able to resist physical pressures.

Proper installation of tension bands is essential for maintaining the overall strength and stability of the fence structure.

Installation Note:

When installing tension bands, they should be evenly spaced along the height of the terminal posts, with one band typically placed near the top, one near the bottom, and additional bands spaced evenly in between.

The number of tension bands required will depend on the height of the fence.

Each band should be used with a tension bar inserted through the end of the fabric, which the band then secures to the post using a carriage bolt and nut.

Tie Wires

Tie wires are short, flexible wires used to attach the chain link fabric to line posts and the top rail.

These wires are essential for securing the fabric at various points along the fence, ensuring it remains evenly distributed and properly tensioned.

• Material: Made from galvanized steel, tie wires are designed to resist rust and corrosion, providing long-lasting durability even in harsh weather conditions.

The galvanization process coats the steel with a protective zinc layer, preventing oxidation and extending the lifespan of the wires.

• Function: The primary function of tie wires is to keep the chain link fabric securely fastened to the line posts and the top rail.

By doing so, they help maintain the fabric’s tension and alignment, preventing sagging and displacement.

Properly installed tie wires ensure that the fence remains stable and visually appealing, while also enhancing its overall strength and resistance to external forces.

Installation Note:

When installing tie wires, they should be wrapped tightly around both the chain link fabric and the post or rail, and then twisted securely to hold the fabric in place.

It’s important to space the tie wires evenly along the posts and rails, with more frequent spacing at the top, middle, and bottom of the fence to distribute the tension evenly.

This will help maintain the integrity and appearance of the fence over time.

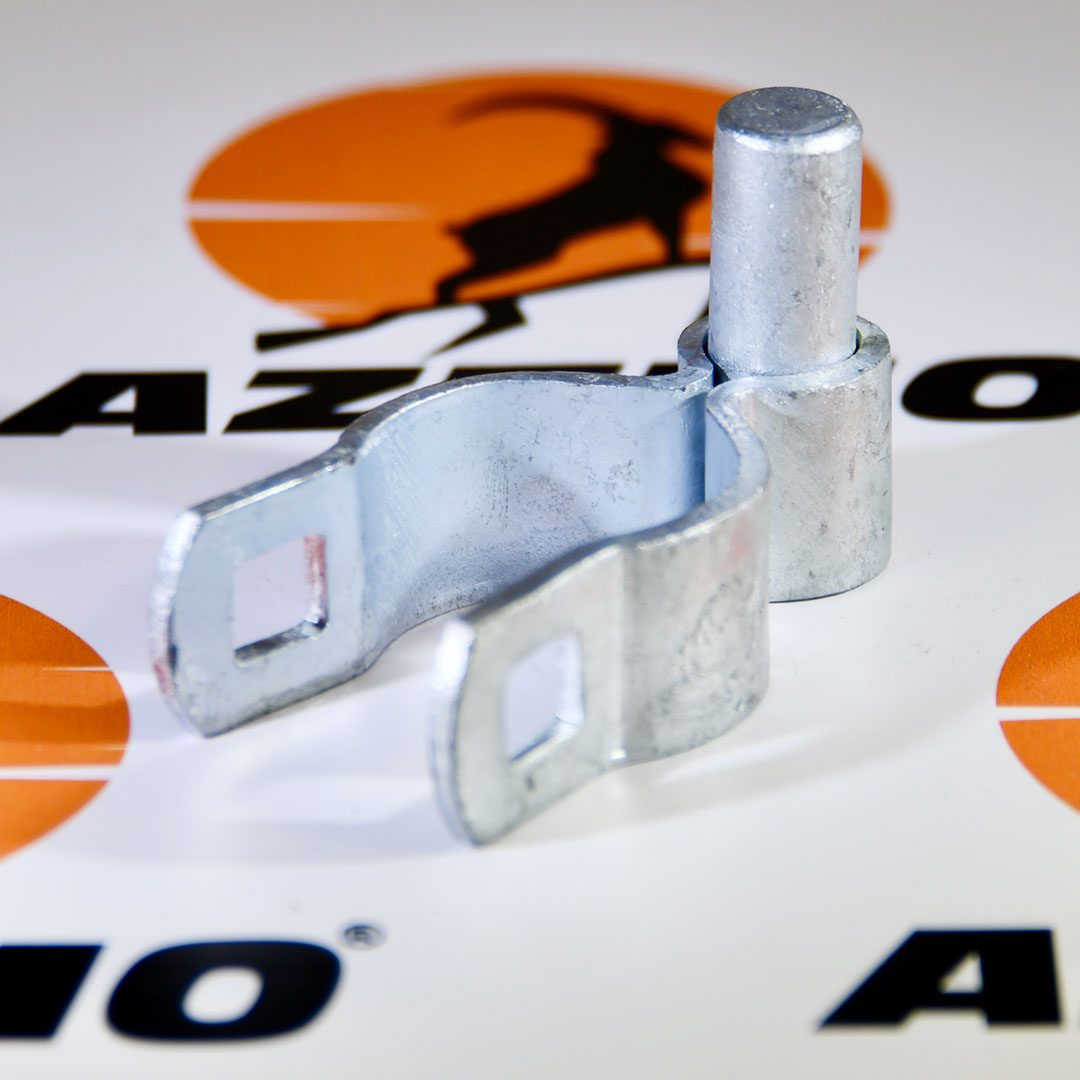

Gate Hinges

Gate hinges are crucial hardware components that allow a gate to pivot smoothly open and closed.

These hinges are designed to provide a reliable and secure attachment between the gate frame and the gate post, facilitating easy and consistent movement.

• Material: Made from galvanized steel, gate hinges are engineered for strength and durability.

The galvanization process involves coating the steel with zinc to prevent rust and corrosion, ensuring that the hinges can withstand exposure to the elements and heavy use over time.

• Function: The primary function of gate hinges is to support the weight of the gate and enable it to swing freely.

Properly installed hinges ensure that the gate operates smoothly and effortlessly, providing easy access while maintaining the security and functionality of the fence.

Gate hinges must be robust and well-aligned to handle the stresses of repeated opening and closing without sagging or becoming misaligned.

Installation Note: When installing gate hinges, it is important to align them correctly on both the gate and the post to ensure smooth operation.

Typically, two or more hinges are used per gate, with one positioned near the top and one near the bottom.

For larger or heavier gates, additional hinges may be necessary to provide adequate support.

Hinges should be securely fastened with appropriate bolts or screws, and regularly checked for tightness and wear to maintain optimal performance.

Gate Latch

A gate latch is a locking mechanism designed to keep a gate securely closed.

It ensures that the gate remains in place when shut, providing security and preventing unauthorized entry.

These latches use the weight of the latch arm to drop into a catch, automatically securing the gate when it closes.

• Material: Made from galvanized steel, gate latches are built to withstand the elements and resist corrosion.

The galvanization process coats the steel with a protective layer of zinc, enhancing its durability and longevity.

• Function: The primary function of a gate latch is to keep the gate securely closed, ensuring that the fence line remains intact and preventing unauthorized access.

A reliable gate latch enhances the overall security of the fence by making it more difficult for intruders to open the gate without proper authorization.

Installation Note:

When installing a gate latch, it is important to position it at a convenient height for easy operation.

The latch should align perfectly with the gate and the catch on the post to ensure smooth and secure locking.

Regular maintenance checks should be conducted to ensure that the latch mechanism operates correctly and that any components showing signs of wear or damage are promptly replaced.

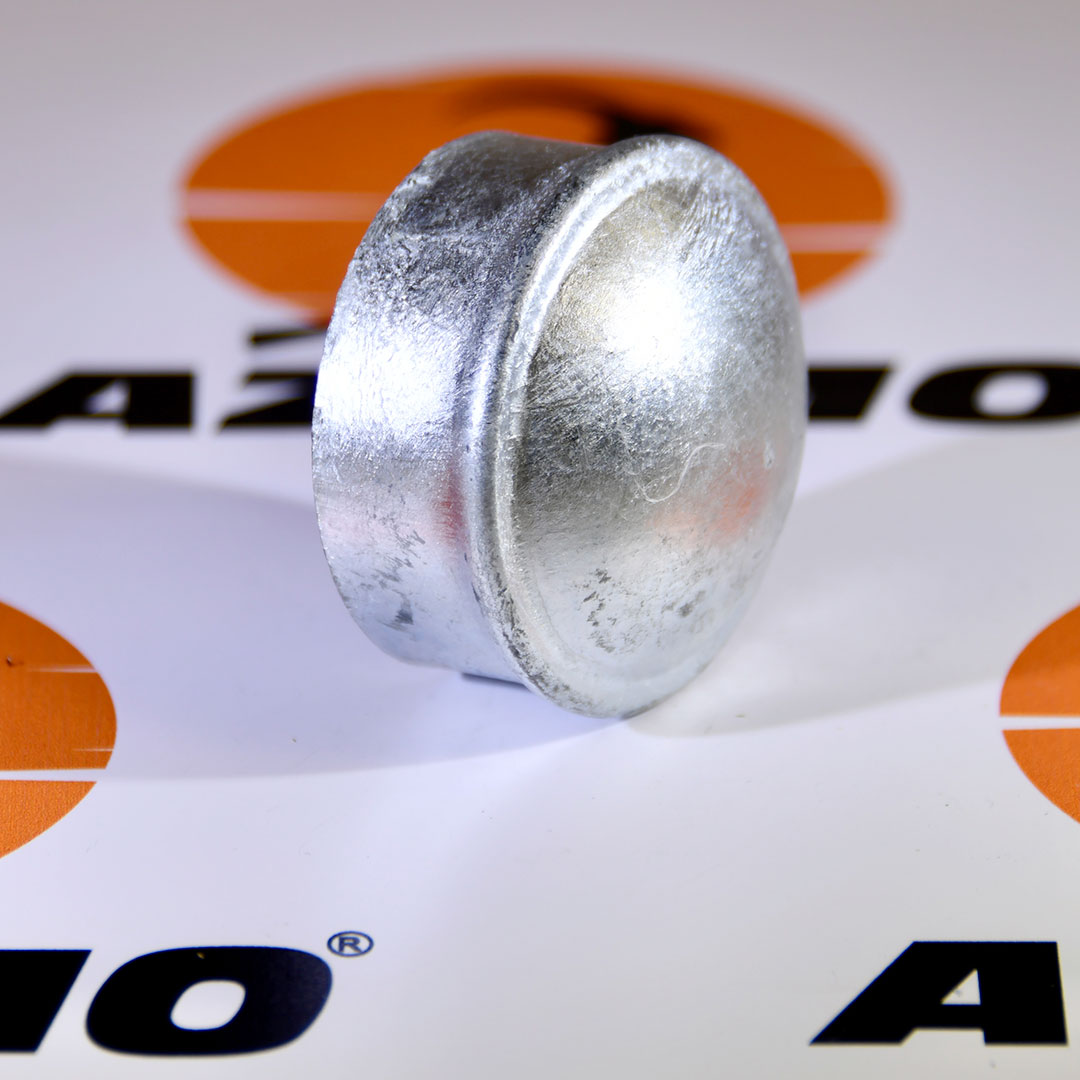

Post Caps

Post caps are protective coverings placed on top of fence posts.

They serve both functional and aesthetic purposes, enhancing the durability and appearance of the fence.

• Material: Post caps are made from galvanized steel or aluminum.

Both galvanized steel and aluminum caps offer excellent rust resistance and durability.

• Function: The primary function of post caps is to prevent water, debris, and other elements from entering the hollow fence posts.

By doing so, they protect the posts from internal rust and damage, significantly extending the lifespan of the fence.

Additionally, post caps provide a finished, polished look to the fence, enhancing its overall aesthetic appeal.

Installation Note:

Post caps should be securely fitted onto the tops of the posts, ensuring a snug fit to prevent them from being dislodged by wind or impact.

For metal caps, a tight press fit or screws may be used to secure them in place, regular inspections should be carried out to ensure the caps remain intact and effective in protecting the posts.

Tension Wire

Tension wire is a sturdy wire that is run along the bottom (and sometimes the top) of a chain link fence.

Its primary purpose is to enhance the stability and security of the fence by preventing the chain link fabric from being pushed out or pulled up.

• Material: Made from galvanized steel, tension wire is highly resistant to rust and corrosion.

This material choice ensures that the wire remains strong and durable, even when exposed to outdoor elements and varying weather conditions.

• Function: The main function of tension wire is to reinforce the lower edge of the chain link fabric.

By securing the bottom of the fence, tension wire helps prevent animals from digging under or intruders from lifting the fabric to gain access.

This added stability is crucial for maintaining the fence’s integrity and security, particularly in areas with soft ground or high levels of activity near the fence line.

Installation Note:

When installing tension wire, it should be threaded through the bottom loops of the chain link fabric or attached using hog rings.

The wire is then stretched tight and secured to the terminal posts with tension bands or other appropriate hardware.

Proper tensioning is essential to ensure the wire provides adequate support without sagging or creating weak points in the fence.

Brace Bands

Brace bands are metal bands specifically designed to secure the top rail and tension bars to terminal posts in a chain link fence.

They play a critical role in providing structural integrity and support to the fence assembly.

• Material: Typically made from galvanized steel, brace bands are chosen for their strength, durability, and resistance to rust and corrosion.

The galvanization process involves coating the steel with zinc, which protects it from the elements and ensures a longer lifespan.

• Function: The primary function of brace bands is to securely fasten the top rail and tension bars to the terminal posts.

By doing so, they help distribute the load evenly across the fence structure, enhancing its stability and rigidity.

Brace bands prevent the top rail from sagging and ensure that tension bars maintain proper tension on the chain link fabric, contributing to the overall strength and longevity of the fence.

Installation Note:

When installing brace bands, they are typically placed at intervals along the height of the terminal posts where the top rail and tension bars intersect.

Each brace band should be tightened securely around the post and attached to the rail or tension bar using carriage bolts or other appropriate fasteners.

Regular inspection and maintenance of brace bands are recommended to ensure they remain securely fastened and continue to provide effective support to the fence.

Carriage Bolts

Carriage bolts are specialized bolts used in conjunction with brace and tension bands to securely fasten them to fence posts in a chain link fence.

They are designed with a smooth, rounded head and a square neck under the head, which prevents the bolt from turning when tightened.

• Material: Carriage bolts are made from galvanized steel, chosen for its strength and resistance to rust and corrosion.

The galvanization process involves coating the steel with a protective layer of zinc, ensuring durability and longevity, even in outdoor environments.

• Function: The primary function of carriage bolts is to provide a strong and secure fastening of brace and tension bands to fence posts.

By securely holding these components in place, carriage bolts help maintain the structural integrity of the fence.

They prevent the bands from loosening over time, ensuring that the fence remains stable and capable of withstanding external forces such as wind and impact.

Installation Note:

When installing carriage bolts, they should be inserted through the holes in the brace or tension band, as well as through the corresponding holes in the fence post.

The square neck of the bolt prevents it from turning while the nut is tightened on the opposite end. This ensures a tight and secure fit that maintains the tension and stability of the fence components.

Regular inspection and maintenance of carriage bolts are recommended to ensure they remain tight and effective in securing the fence structure.

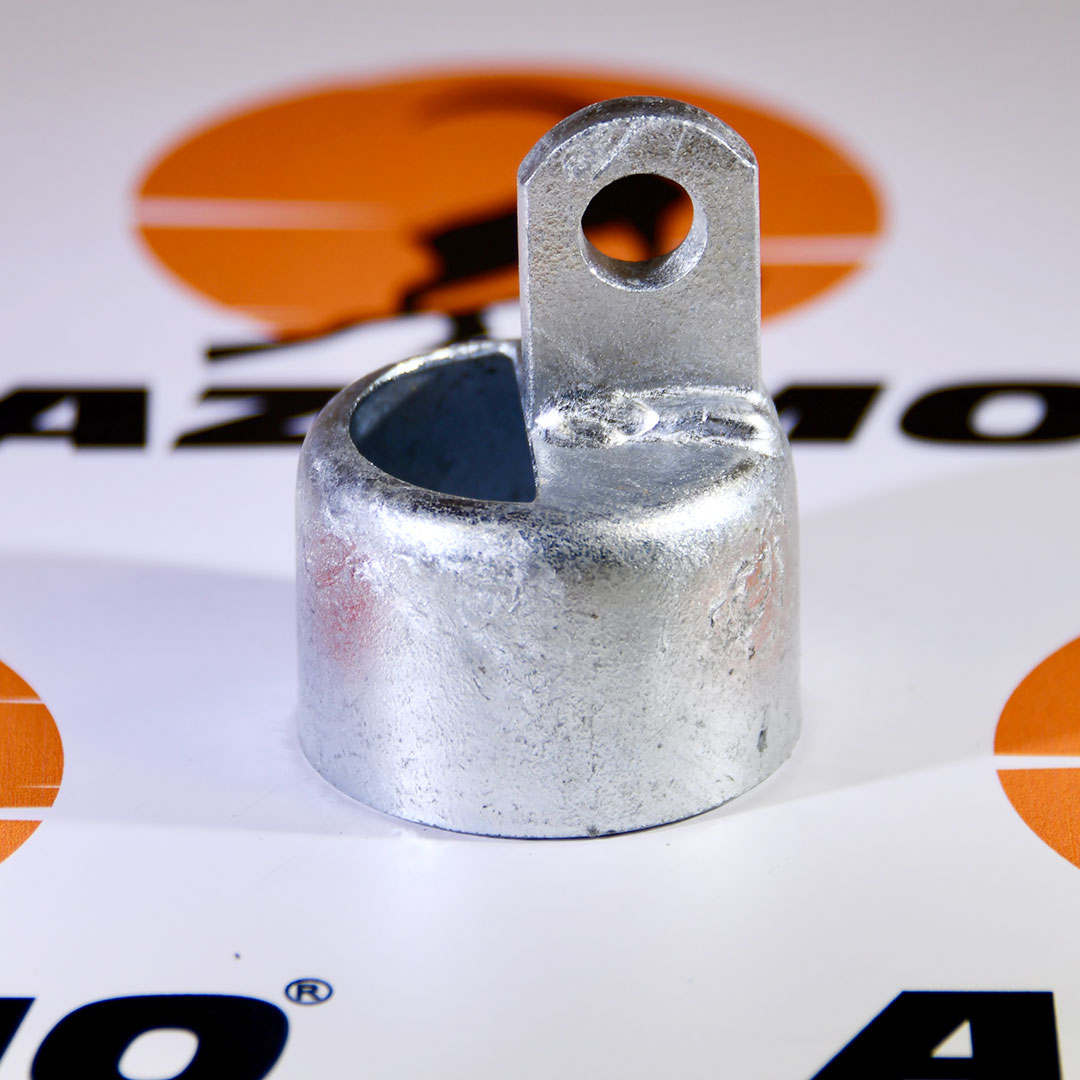

Loop Caps

Loop caps are specially designed caps with loops or tabs that facilitate the connection between the top rail and the line posts in a chain link fence.

They provide a secure and stable attachment point for the top rail, enhancing the overall strength and integrity of the fence structure.

• Material: Loop caps are commonly made from galvanized steel or aluminum.

These materials are chosen for their durability, corrosion resistance, and ability to withstand outdoor elements.

• Function: The primary function of loop caps is to securely fasten the top rail to the line posts.

By looping around the top rail and attaching to the line posts, loop caps ensure a continuous and stable connection.

This prevents the top rail from slipping or becoming dislodged, maintaining the alignment and tension of the fence fabric.

Installation Note:

When installing loop caps, they should be positioned at regular intervals along the top rail where it intersects with each line post.

The loop of the cap should securely wrap around the top rail, and then the cap is fastened to the line post using screws or bolts.

Proper installation of loop caps ensures that the top rail remains securely attached, contributing to the overall stability and durability of the chain link fence.

For a quotation or speak with our experienced consultants,

please call (213) 792 0040.

AZEMO Wire

Your Premier Destination for High-Quality Chainlink Fencing Solutions

18333 Pasadena St. Lake Elsinore, CA 92530, USA

Call Us : +1 (213) 792 0040